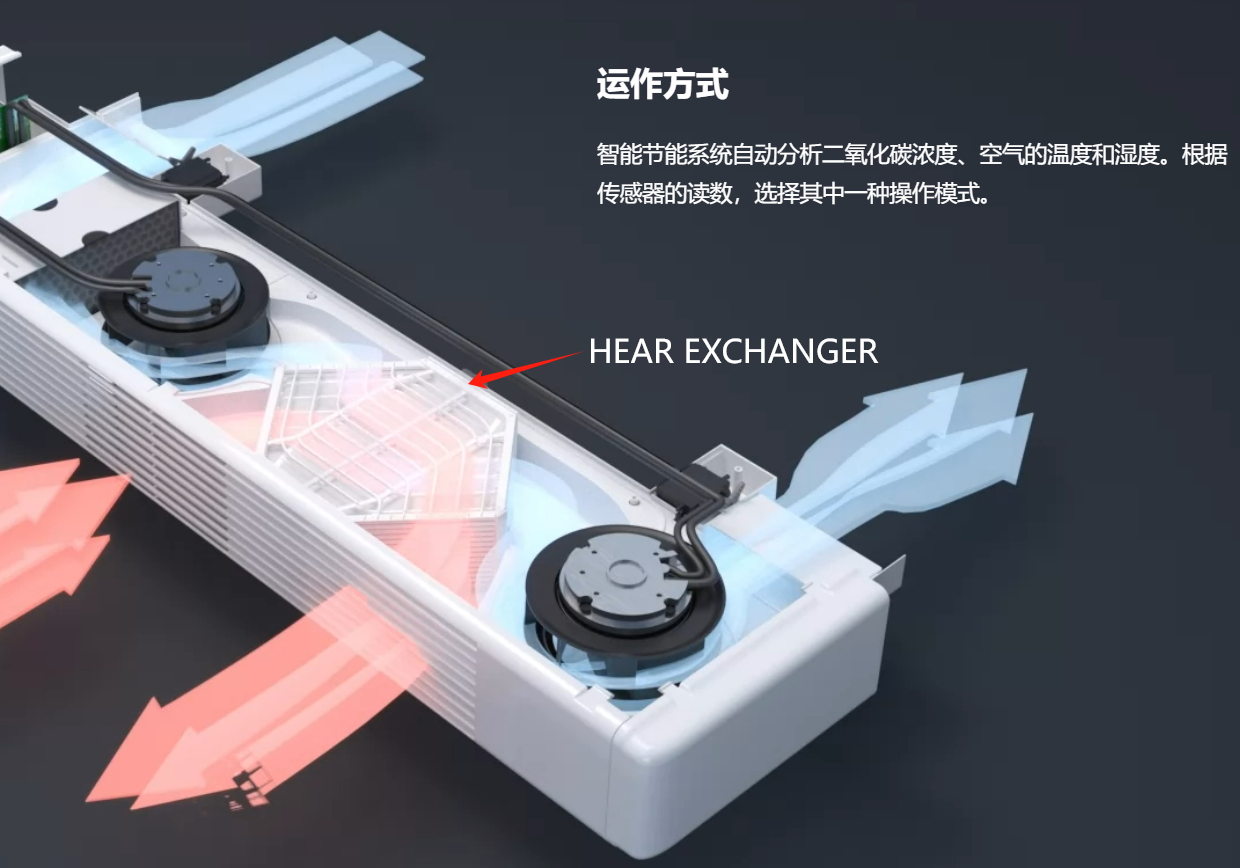

C-Erv Enthalpy Heat Exchangers Making Line Production Line

Product Description

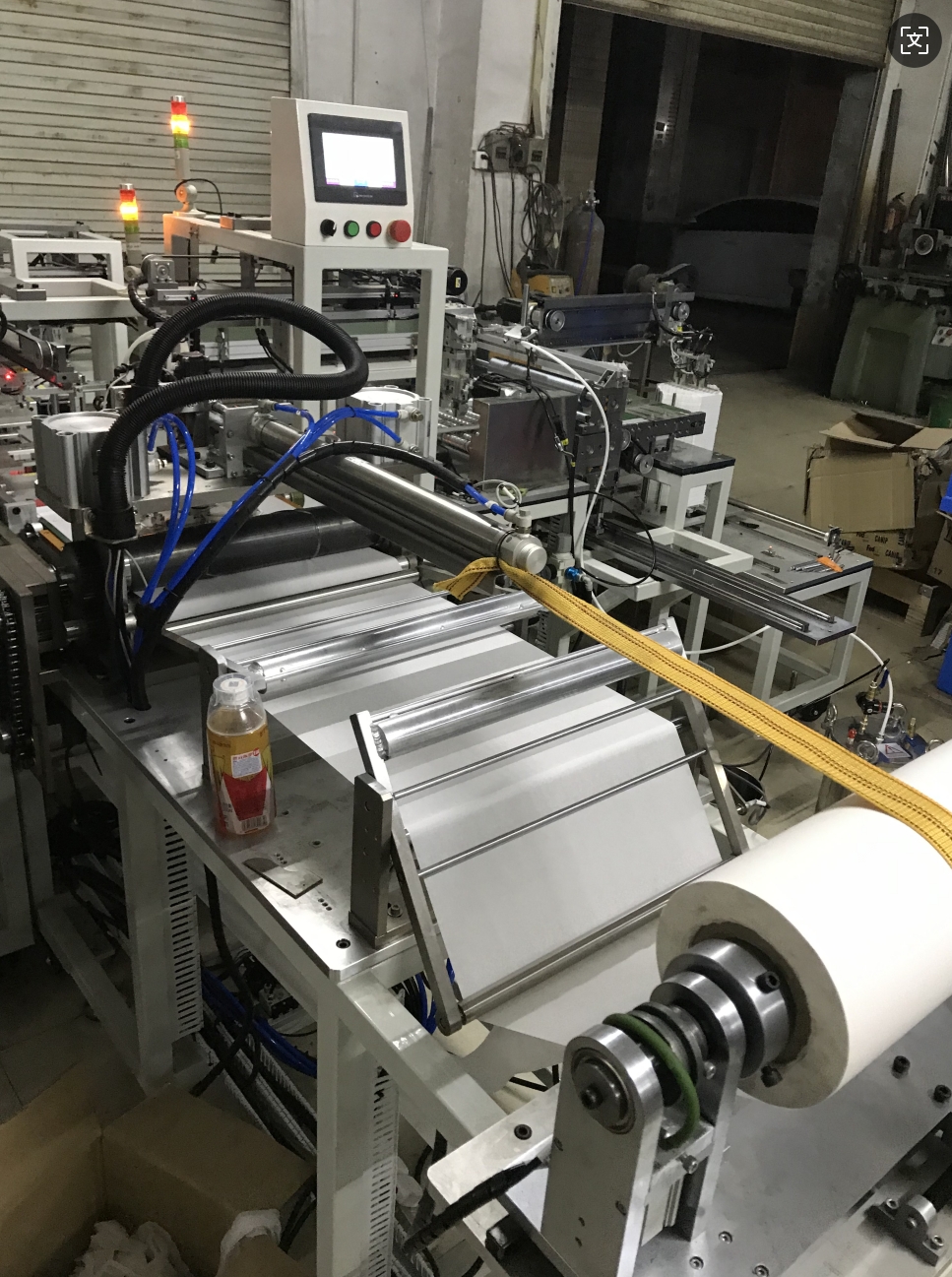

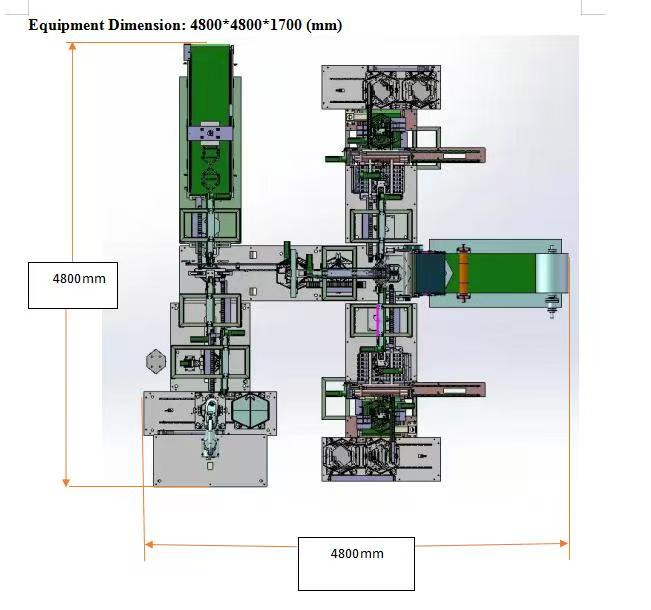

TY-DF01 Automatic assembly equipment for heat exchangers

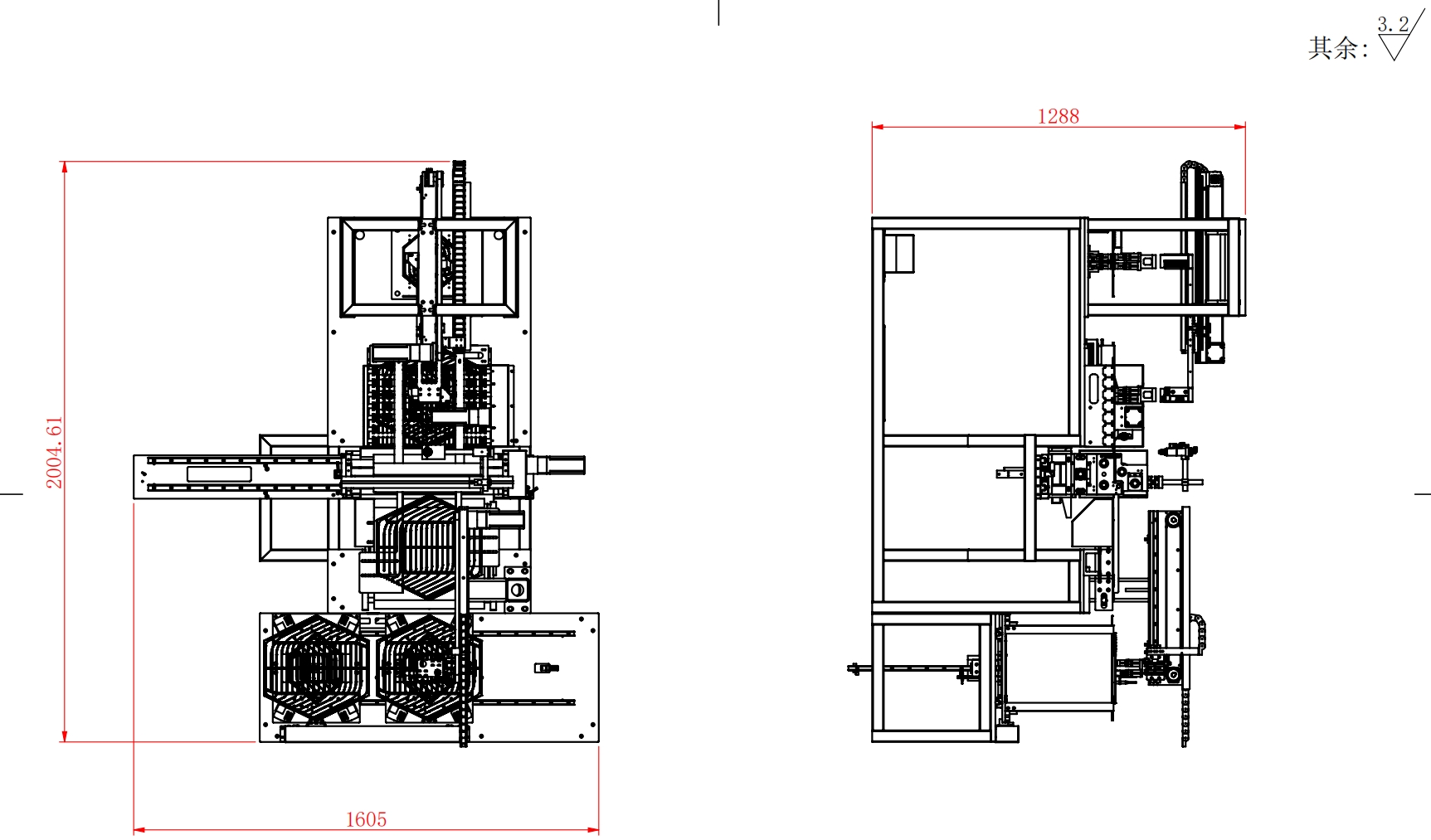

Device parameters

Equipment model: DF01-ERV201

Total weight of the equipment: 2T

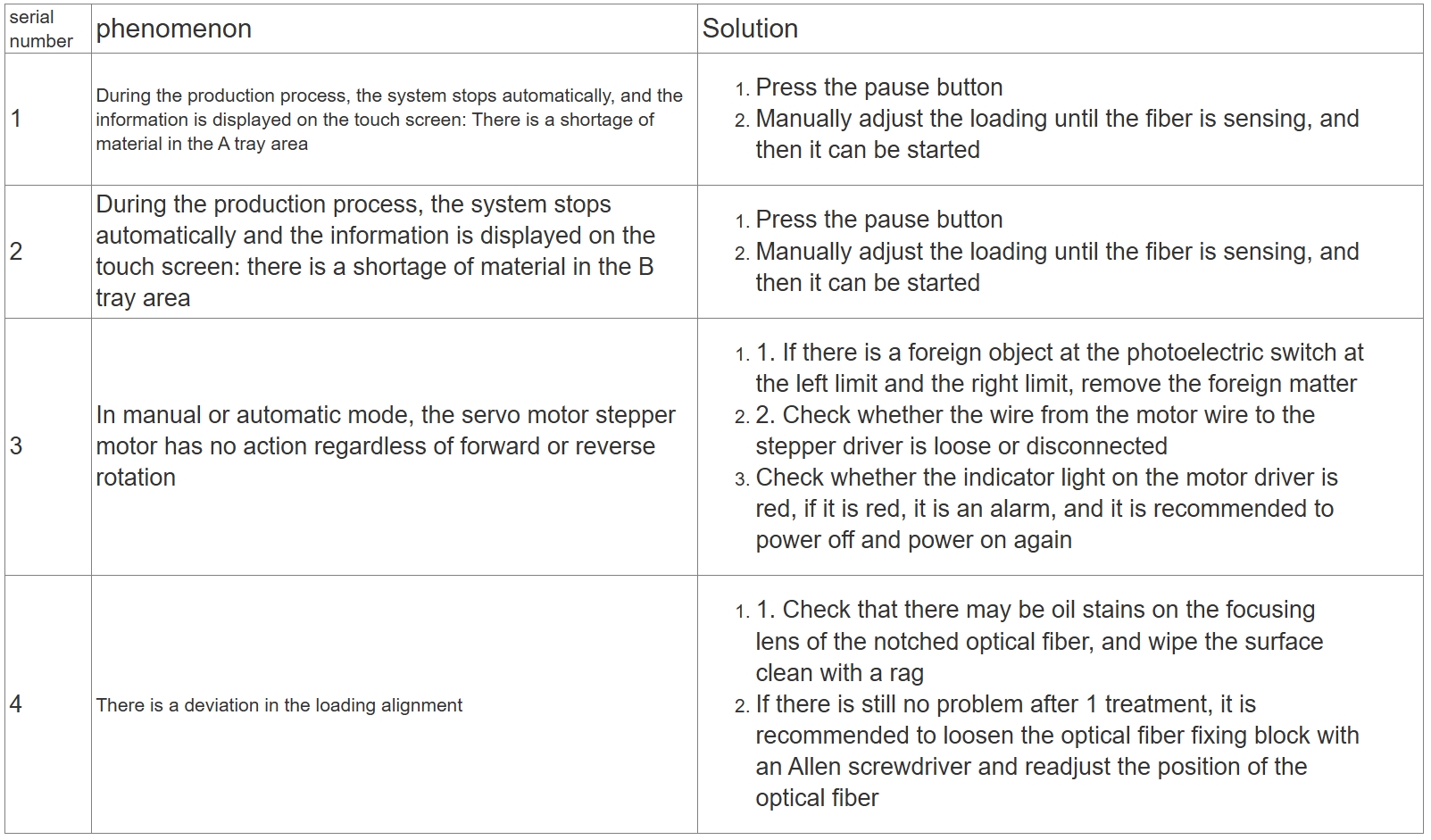

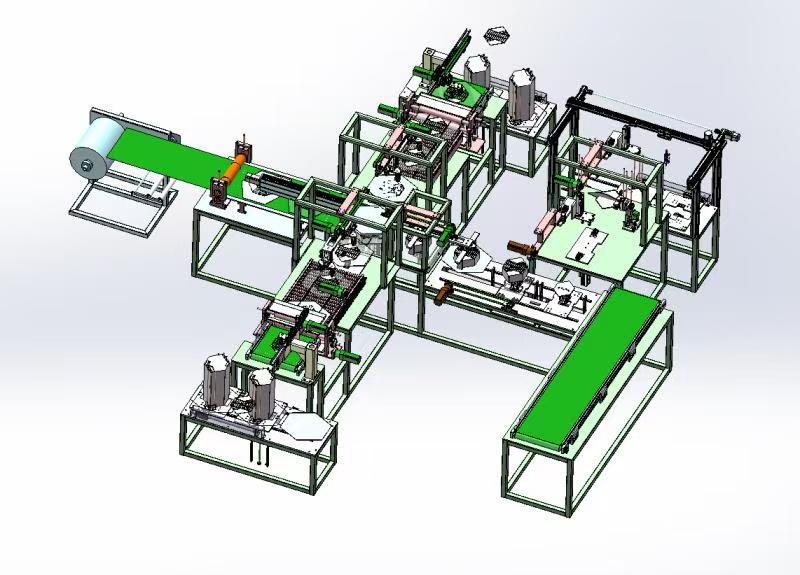

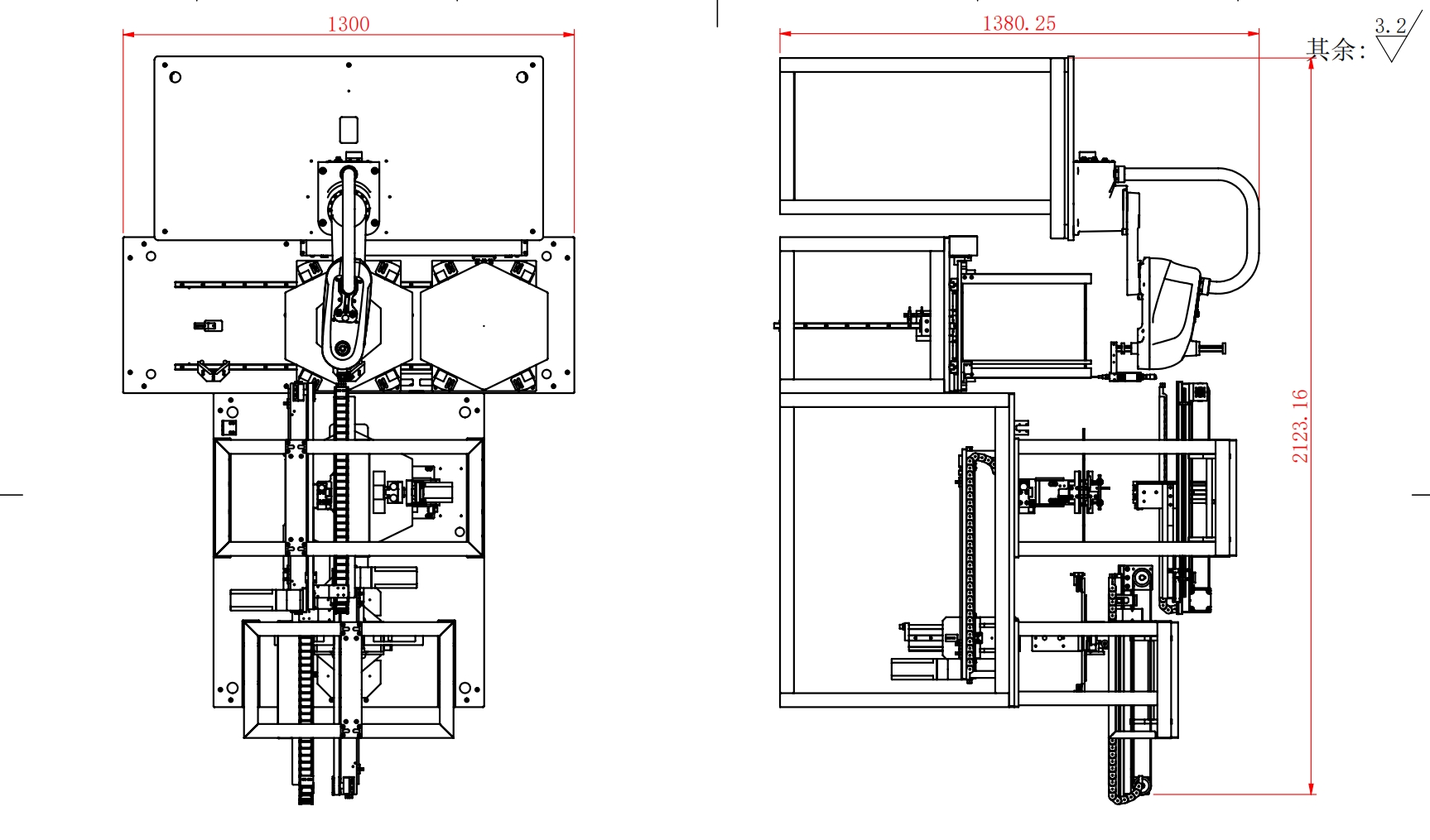

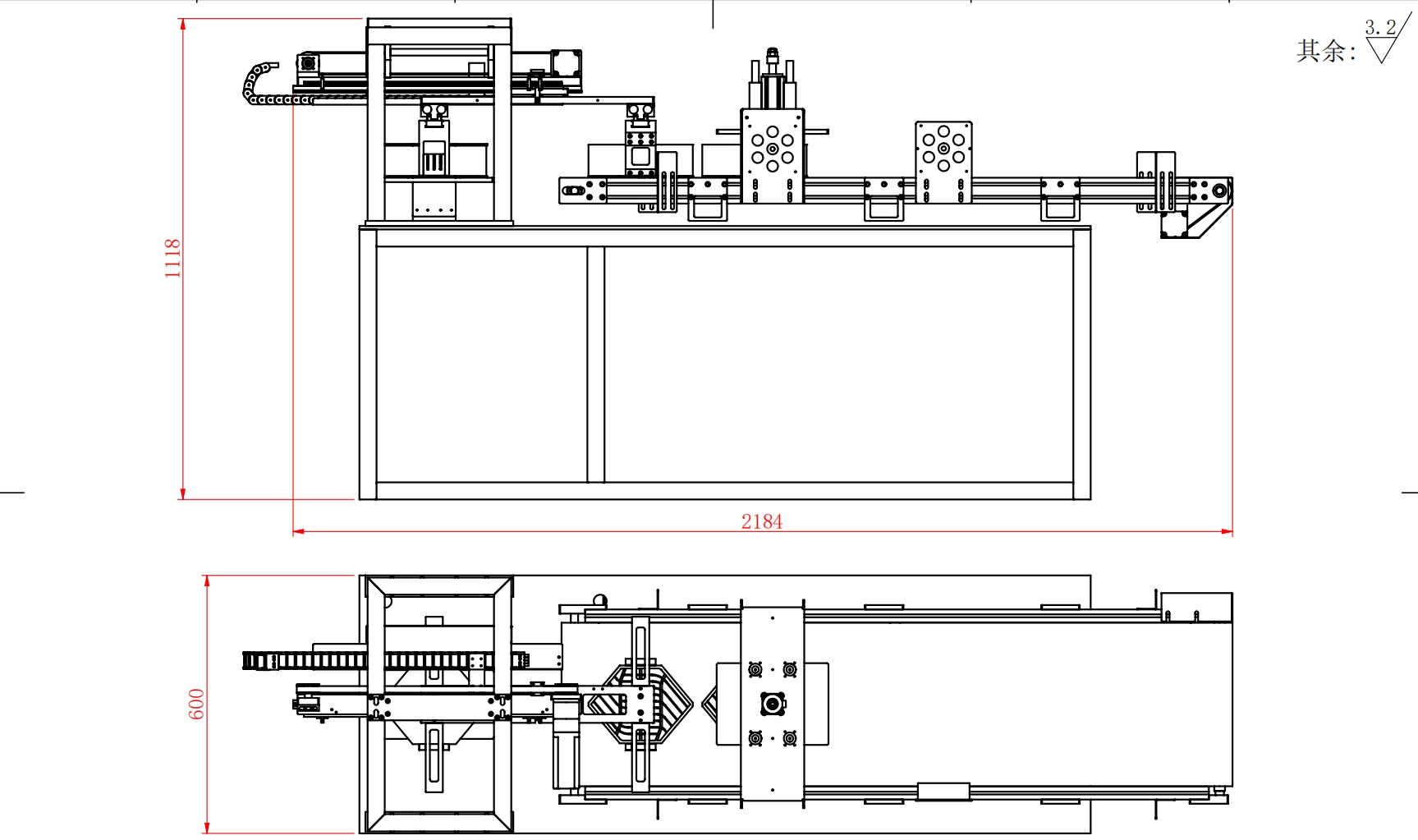

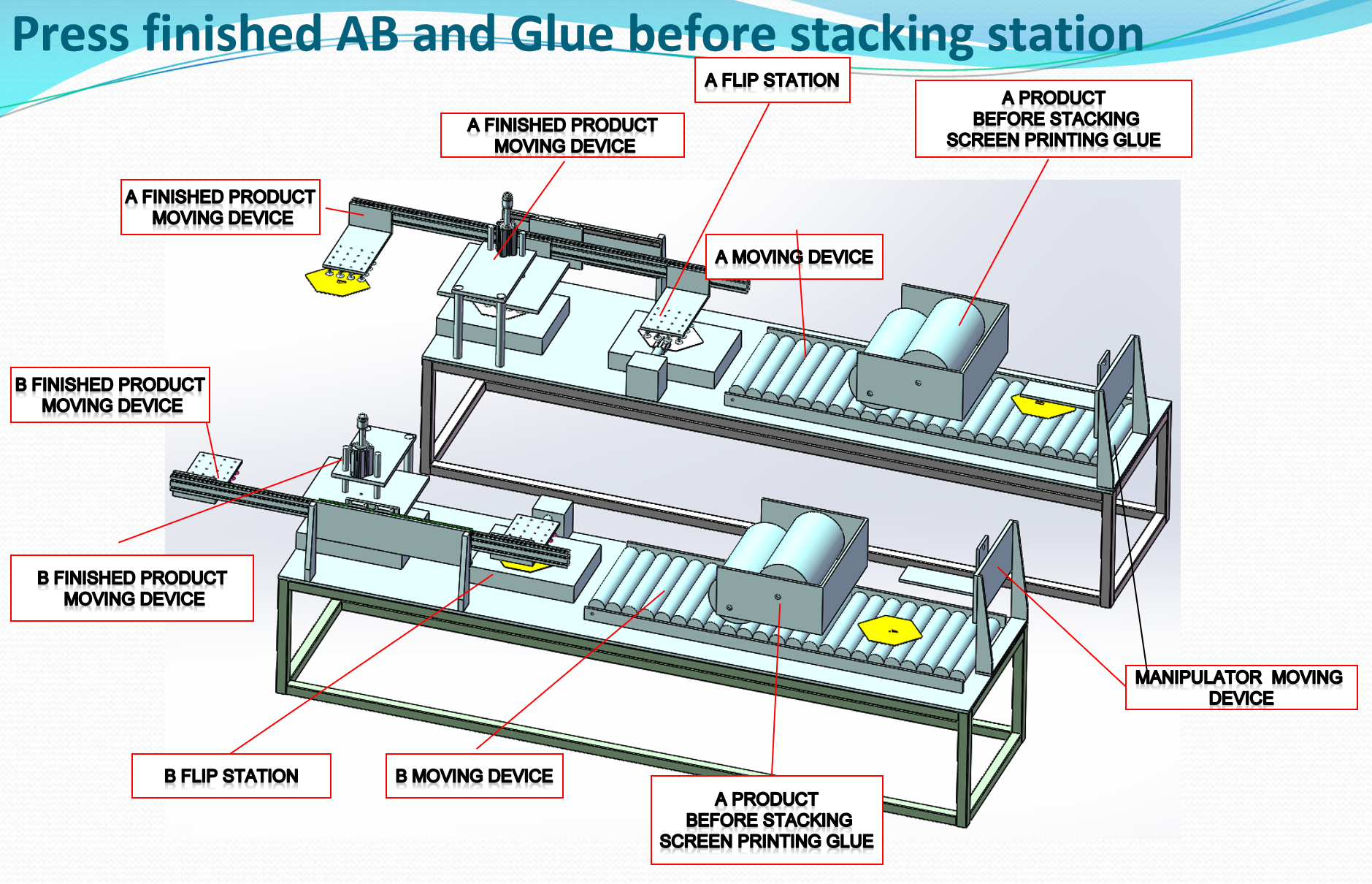

The device is divided into six parts

1. Paper cutting mechanism

2. A disc feeding and rolling mechanism

3. B disc feeding and rolling mechanism

4. Paper, AB material tray, end cover assembly mechanism

5. End cap dispensing mechanism

6. Finished product assembly line mechanism

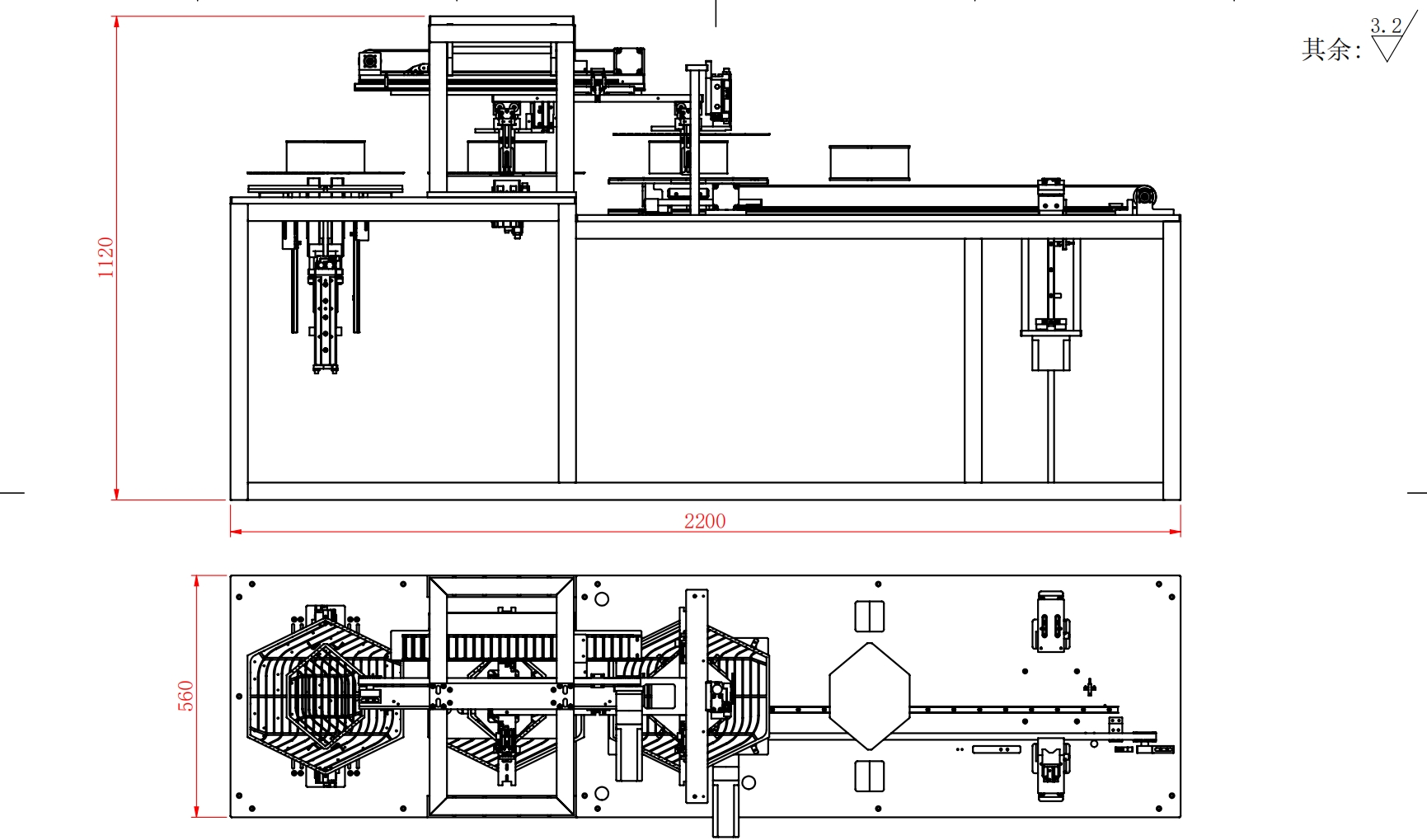

Power supply voltage: AC200V - 240V

Total power of power supply: 1.5KW

Air pressure: 0.5 - 0.7 Mpa

Capacity: 20 - 25 Pcs/H

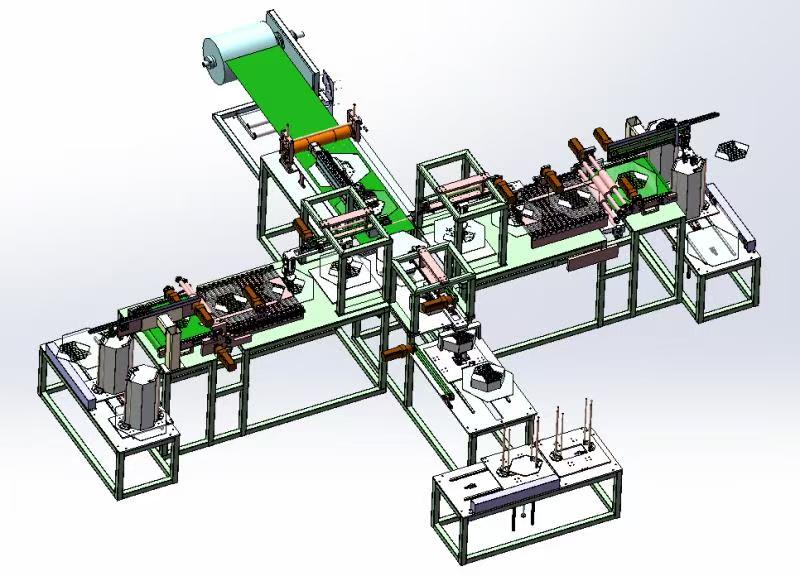

This equipment will realize: automatic paper cutting, automatic gluing, automatic assembly heat exchangers functions ;

The equipment adopts the online fully automatic design concept, and all processes are completed automatically.

1 Working source:AC220V

2 Working pressure :0.4-0.6 Mpa

3 Maximum power : 4KW

4 Productivity:

ERV212:40-50pcs Finished Heat exchangers/H

ERV366:30-40pcs Finished Heat exchangers/H

5 Lifetime:≥10years(Excluding consumables)

Safety precautions

This manual provides some information for users when using the TY-DF01 device. In order to ensure safe operation and smooth production, the following two points need to be noted:

1) It is forbidden for non-professionals or personnel who have not obtained relevant training certificates in electrical fields to open the electrical box. It is forbidden to make any changes to the electrical wiring and gas circuits in the electrical box.

2) It is forbidden to contact the moving parts of the machine parts with any part of the body during the operation of the machine, and if you need to check and repair, be sure to suspend the machine or turn off the power of the equipment. Repairs are carried out on a safe premise.

Preparation before production:

1. Cleaning and cleaning: Be sure to clean the work surface, check whether the cylinder joints and moving parts are loose, and tighten them if there are abnormal and loose parts.

2. If there is oil stain in the moving part of the cylinder, please wipe the oil dirt with a rag, and then lubricate the oil on the moving part of the cylinder again.

3. Ventilation: dry and clean air source, range: 0.5-0.7 Mpa. Operation method: Push forward the hand slide valve on the right side of the machine near the air conditioning combination triplet by hand, and the pressure display gauge on the triplet shows the range of 0.5-0.7 Mpa.

4. Power-on: power supply range: AC220V±0.5%, 50HZ. Operation method: Turn on the power of the three operation panels of the equipment and turn on the four-axis robot, and the equipment has been successfully powered on. The operation process of the four-axis robot: the key lock key is aligned automatically, and then press the start button. Other operating functions must be familiar with the operation manual of the Zhongweixing four-axis robot

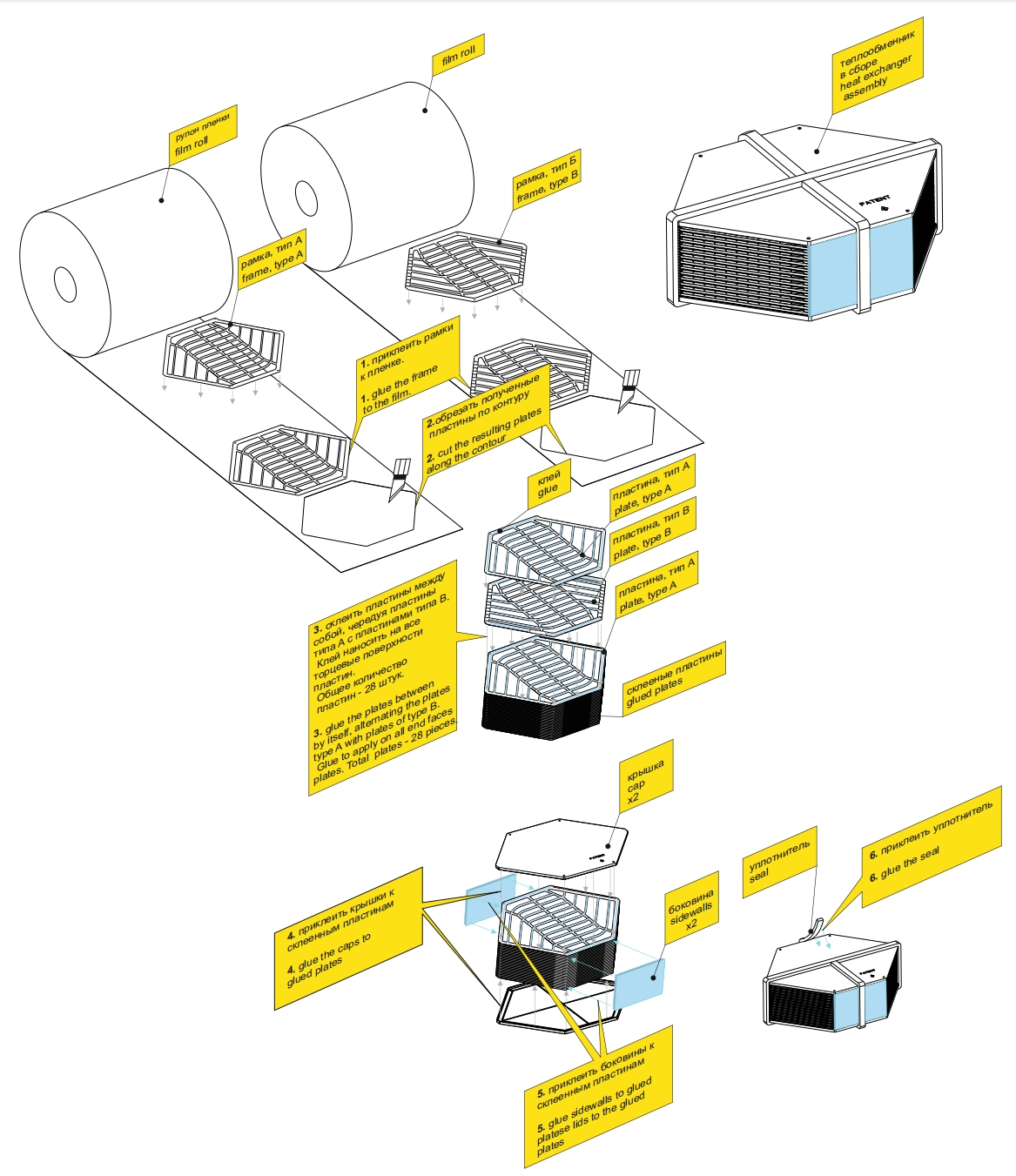

Common alarms and handling methods

The following table lists common general alarms and how to resolve them: