High Precision Self-Adhesive Custom Semi-Automatic Labeling Machine

Product Description

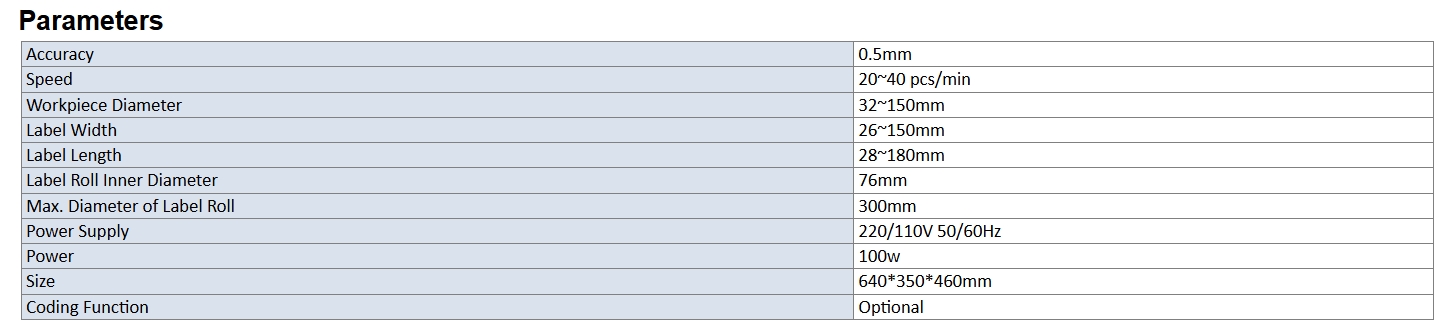

TY-LM350 High Precision Self-Adhesive Custom Semi-Automatic Labeling Machine

Overview

Quick Details

Type:Labeling Machine

Condition:New

Application:Apparel, Beverage, Chemical, Food, Machinery & Hardware, Medical

Packaging Type:Cartons

Packaging Material:Paper, Plastic

Automatic Grade:Semi-Automatic

Driven Type:Electric

Voltage:220/110V 50/60Hz

Place of Origin:Guangdong, China (Mainland)

Dimension(L*W*H):650*450*450

Weight:20kg

Certification:ISO 9001

After-sales Service Provided:Online support, Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, No overseas service provided

Warranty:1 Year

Speed:25 - 50pcs/minute

Accuracy:±0.5mm

Applicable bottles of diameter:10-150mm

Label Roll Inner diameter:75mm

Label Length:15-220mm

Label roll External diameter:300mm

Quality:Excellent

A Semi-automatic Round Bottle Labelling Machine is an ideal equipment for labelling of household chemicals, food and beverage, pharmaceutical, chemical, and the round bottle in the other light industry products on the packaging.

This machine is suitable for round bottles of various sizes and the production of small quantities of many varieties.

This machine can be used in stand-alone label only

Usage Instructions

- It applies advanced labeling agencies to ensure that the labeling accuracy.

2.It hasbottle label for avariety of specifications with strong adaptability.

3.Label light sensitivity is adjustable. For label backing paper of different transmittances, it could compare and adjust the sensitivity and compare and make the best adjustment to the label of different lengths to ensure the normal feeding and smooth and accurate labeling.

4. All agencies, including the rack, and feeder, barrier boom and fastener adopt stainless steel and aluminum materials, which never rust or produce any pollution. It ensures GMP environmental requirements.

5. System control components all have ISO certification and undergo a rigorous assessment of incoming plant test to ensure the reliability of the various functions.

Features

You can have extra functionality like coding batch number or expire date on the label while you labelling.

These two machines works together very well.

As you can see in the picture below, it sits on top theTY-LM350 labelling machine and working accordingly.