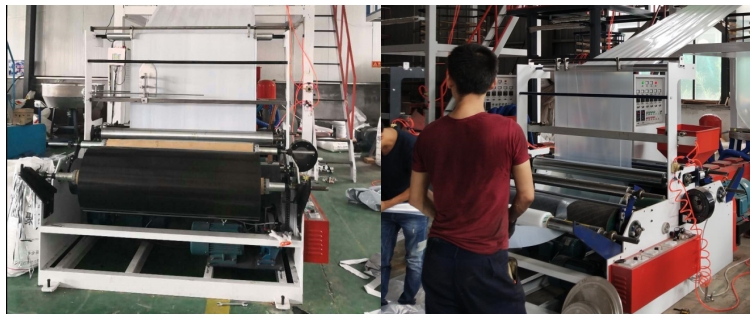

Automatic PE Film Blowing Machine

Product Description

TY-1200HDPEAutomatic PE film blowing machine

1.Feature:

1.1, The machine take the HDPE or LDPE,LLDPE as raw material, through heating, extrusion, blowing, stretch, winder and final be roll thin film.

1.2, The finished plastic thin film is widely used for supermarket bag, garbage bag, various plastic package bag, farmland film.cote film and compound thin film.

1.3,The machine adopts back-to-back double-winding for the production and processing of PE heat shrinkable film.

3.Main Technical Specification

Detail specification

Screw:

Screw Diameter (mm): Ф65mm

Screw L/D ratio: 30:1

38CrMoAlA Polished with Nitrided Treatment

hardness of heat treatment: screw HV≥740, barrel HV≥900

depth of hardening:0.6-0.7mm

brittleness grade: ≤2 grade

Screw Speed 10-100r/min

Motor:

Driving motor: 22kw M-4 variable frequency motor

Heating Zone: 7(zone) Screw:4(zone) Three-way connection device:1(zone) Die:1 (zone) Rotating head:1(zone).

Cooling way: Air cooling

ScrewHeating capacity: 4(zone)

heating power:9.6kw

Feeding method: Manual feeding.

Screen changer

Changing method: Manual filter net

Temperature control table: intelligent dual digital display

Inverter:22kw VVVF controller

Reducer: 173# Hard surface gear reducer

Reduction ratio: 10:1

Extrusion Die

The working mode of the die: rotating the die, the motor drives the die to rotate 360 degrees, increasing the flatness of the film winding

Die Diameter: LDPEФ220mm or as per customer's choice.

Processing way: Adopt numerical control processing center

Die gap: 1.8mm

Die Heating Control (zone): 1

Heating Capacity: 3.5kw

Three-way connection device:1(zone) 2.2kw

Type of air-ring: dual lip high effective cooling to air ring

Air blower: 3 kw x1pcs

Cooling air ring: 780mm High-pressure double air outlet ring

Duct diameter:φ80mm

Haul -off Unit

Roller width (mm): 1300

Effective width (mm): 1200

Take-up motor: 1.5kw Turbine direct-coupled variable frequency motor

Reducer: 10:1

Take-up speed (M/minute): 0-80m/min

Speed control mode: frequency converter speed regulation

Inverter power: 1.5kw vector inverter

Type of roller: rubber roller and metal roller

Pressure roller adjustment mode: pneumatic control

Corona treater:1200mm

Total height of rack:5000mm

Winding Unit

Type of winder: Double broken double

Working method: surface friction type

Roller width (mm):1300

Effective width (mm): 1200

Roll Diameter: 600mm

Automatic length counting

Winding motor: AC Torque Motor x3(10N.m)

Tension controller: by torque motor 20Ax3

Winding speed (M/min): 0-60m(M/min)

Reel: 4pcs Mechanical shaft (unloading screw)

3. Main part configuration