Eco-Conscious 3D Shopping Bag Production and Manufacturing Machine

Product Description

TY-X700-3D Eco-friendly Shopping Bag Production Equipment Non-woven Takeaway Bag Manufacturing Machine

Suitable bags

Line features:

This equipment is the most advanced bag making equipment in China, which can automatically weld the handle during bag making. The welding speed of the handle can reach 30-75 pieces/minute, and can produce handbags, flat bags, edge pockets, and rope bags. This equipment is suitable for raw materials such as non-woven fabrics, capable of processing various specifications and shapes of non-woven bags. It is operated using an LCD touch screen, equipped with progressive length setting, photoelectric tracking, computer automatic positioning, computer automatic edge correction, accurate, stable, and automatic counting. It can automatically alarm, punch holes, weld handles and other industrial control equipment.

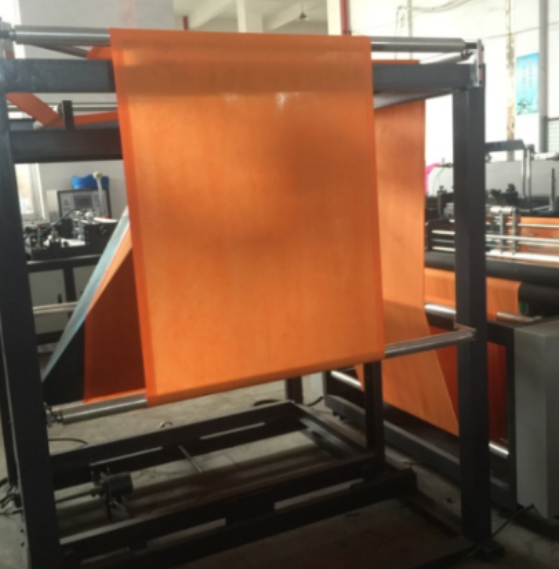

Bag making and feeding section:

Equipped with an automatic feeding device, which does not require manual lifting, enabling one person to operate the machine. The automatic material cutting device automatically shuts down after the material production is completed, eliminating the need for repeated threading processes and saving time. The feeding shaft is an inflatable shaft, suitable for use with national standard paper cylinders with a diameter of 7.6cm. After inflation, the non-woven paper cylinder is clamped tightly, making it easy to use. It is equipped with an automatic deviation correction function, which automaticallycorrects uneven fabric.

The flat folding part of the bag making machine is equipped with an automatic folding function for the bag opening. The folding function of the non-woven bag opening is achieved here, and the threading function is used when making a rope threading bag. Two sets of 70 round head ultrasonic waves are used to fix the folding part of the non-woven bag.

Fold in half: Fold the folded edge of the non-woven fabric in half

Bag making edge insertion part:automatic edge insertion at the bottom of the non-woven bag, and edge insertion on both sides of the non-woven vest bag

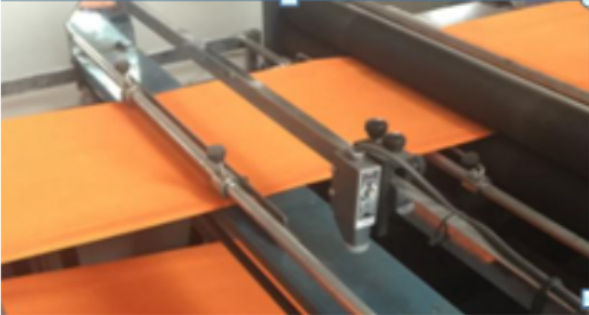

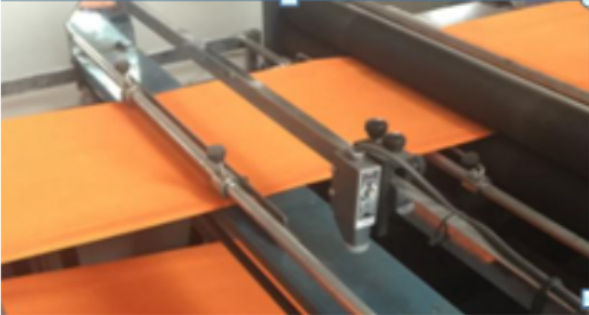

Bag making machine photoelectric tracking part: This device is equipped with photoelectric eye tracking and color labeling to ensure that the size of each bag is standard.

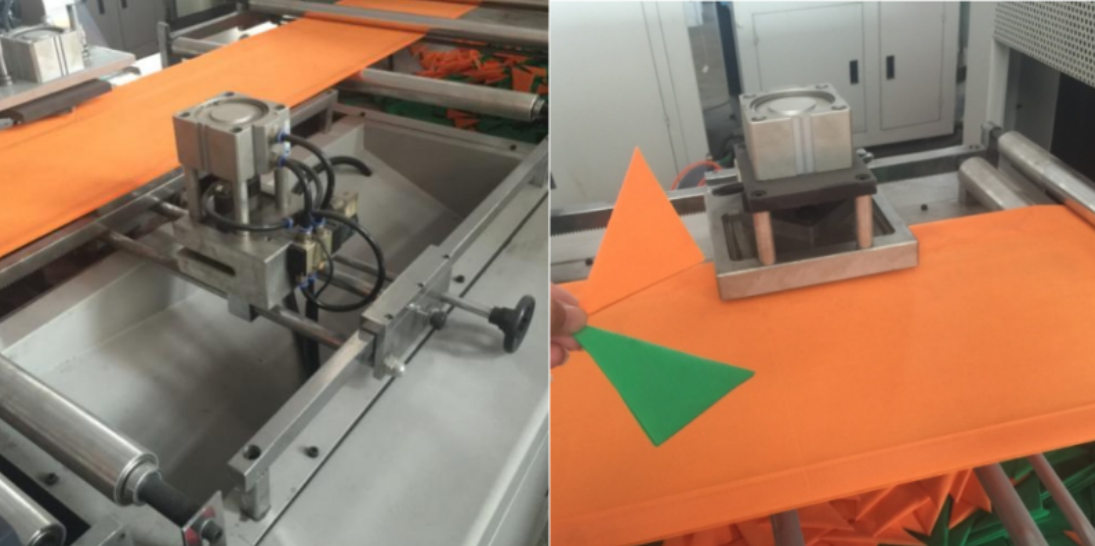

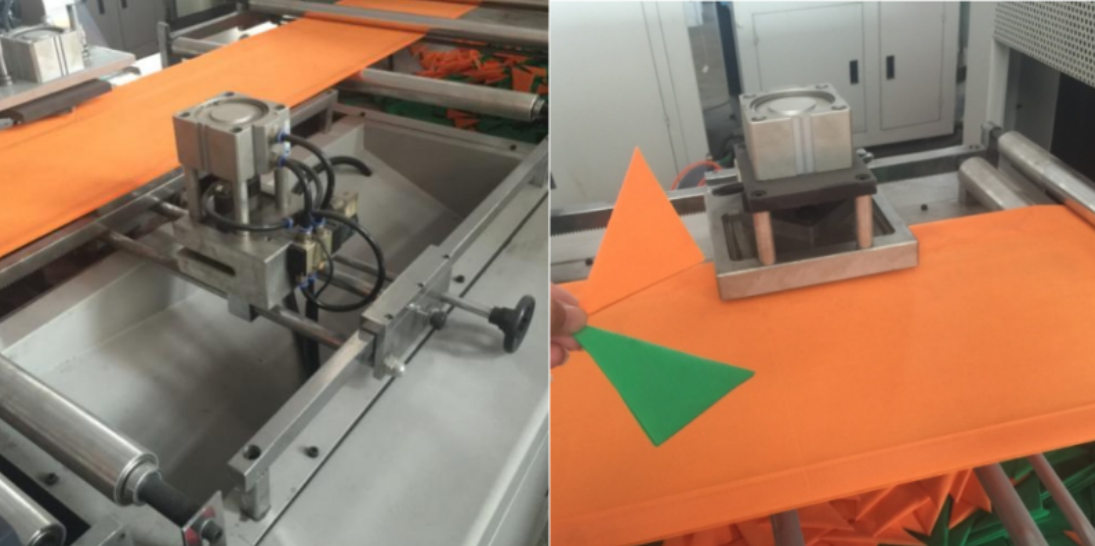

Sealing triangle part of bag making machine:

When making a three-dimensional bag, seal the bottom of the inserted three-dimensional bag with ultrasonic waves on both sides to create a three-dimensional feeling at the bottom of the non-woven fabric. (The purpose of placing a roll of PET film on the machine: during the sealing process of the triangle, a layer of PET film needs to be separated to prevent the two layers of non-woven fabric at the bottom from sticking together when sealing the triangle.)

Punching part of bag making machine:

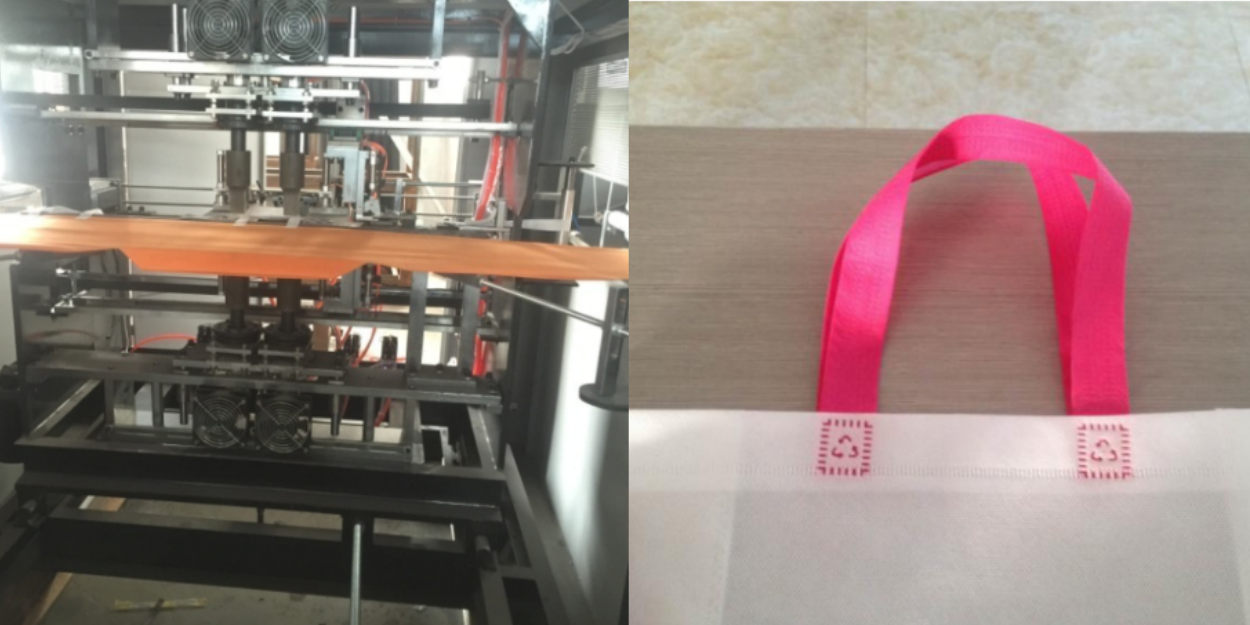

The welding handle part of the bag making machine: The automatic upper handle is welded to the bag through ultrasonic waves, and the internal part is driven by a motor, with fast speed.

Bag making machine edge sealing part cutting blade part:

Seal both sides of the non-woven fabric through ultrasound and shape the non-woven fabric bag. Cut the formed non-woven bag through a blade, collect the finished product, and complete the bag makingprocess.